Top Suppliers Aluminum Conduit Corrosion Resistance - Resistor for Oil Drilling for braking resistor – Wepower

Top Suppliers Aluminum Conduit Corrosion Resistance - Resistor for Oil Drilling for braking resistor – Wepower Detail:

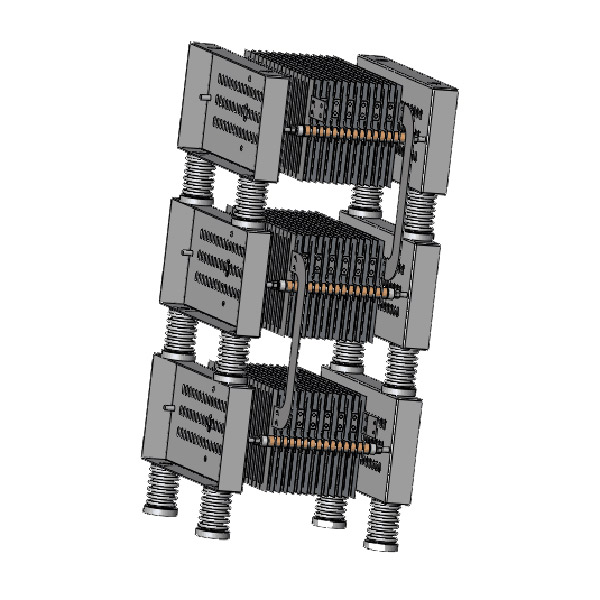

█ Structural characteristics

1.The resistor adopted modular design,and resistor power : 50kw~10000KW.

2.The special structure of resistor, can improve the heat dissipation capacity and have more surface load and is able to current uniform distribution; The resistor bank are connected by welding, which can endure the various shock and vibration. The resistor banks are separated by porcelain pieces, which have better vibration and insulation.

3. The advanced and mature automatic production lines are used to insure resistance tolerance≤2% .In addition, the special reinforced rib resistance belt can make resistance bank smaller and reduce the size of the product.

4.Teamwill resistor,not only choose the high standard materials and devices, but also strictly control the quality of each production process, ensure higher quality than the standard requirements.

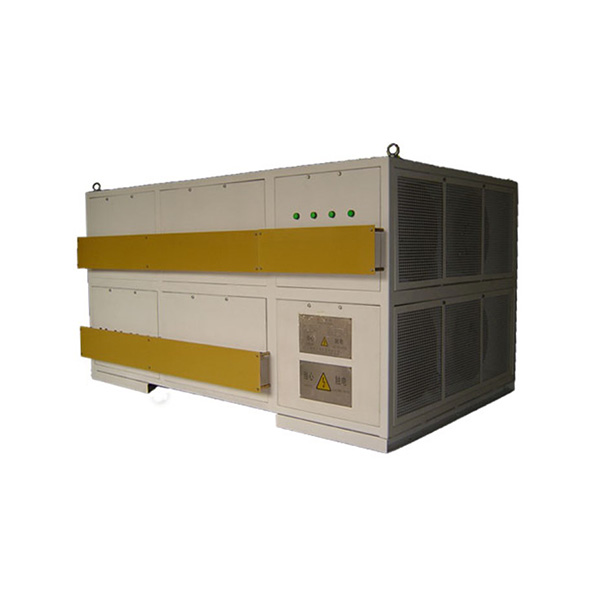

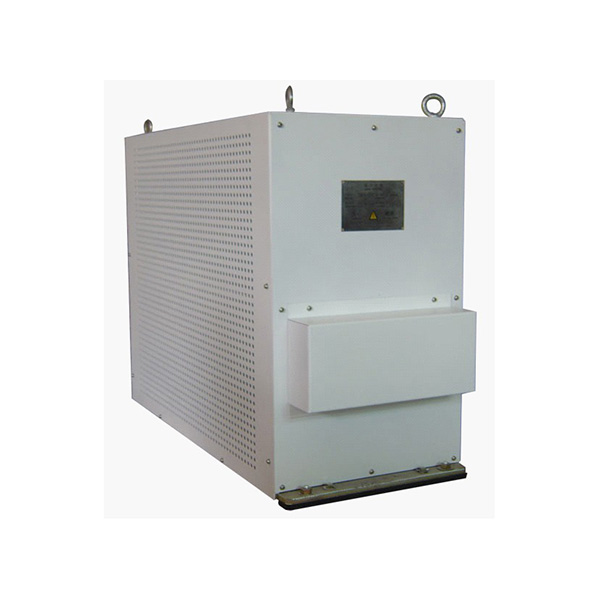

5. The large power resistor will adopt forced air cooling mode to ensure the reliable heat dissipation. And the products install pressure switch and temperature sensor to ensure the reliability of the resistors.

6. All products subject to strict temperature rising test, salt spray test, withstand voltage test to ensure working normal in all kinds of bad conditions.

█ Product specifications

|

Model |

Rated power |

(Ω) Resistance |

Time(S) |

Boxing Dimensions |

Cooling way |

||

|

L(mm) |

W(mm) |

H(mm) |

|||||

|

TWOR |

50KW |

2.35Ω |

20s+70s |

736 |

482 |

1320 |

Natural |

|

TWOR |

100KW×4+20KW |

2.72Ω×4+8Ω |

1min+4min |

2420 |

1000 |

1200 |

Forced air |

|

TWOR |

100KW×6+25KW |

2.72Ω×6+6Ω |

20s+70s |

1800 |

1000 |

1730 |

Forced air |

|

TWOR |

100KW×8+25KW |

2.3Ω×8+4Ω |

20s+70s |

2150 |

1200 |

1200 |

Forced air |

|

TWOR |

460KW×2 |

1.0Ω×2 |

20s+70s |

2500 |

1500 |

1000 |

Forced air |

|

TWOR |

460KW×2+12.5KW |

1.0Ω×2+8Ω |

150s+450s |

2780 |

1500 |

1000 |

Forced air |

|

TWOR |

460KW×3+6.25KW |

1.1Ω×3+4.3Ω |

150S+450S |

2530 |

1200 |

1200 |

Forced air |

|

TWOR |

460KW×4 |

1.0Ω×4 |

20S+70S |

2885 |

1300 |

1050 |

Forced air |

Noted:For other technical parameters & requirements, please contact with our company’s business man.

Product detail pictures:

Related Product Guide:

We've one of the most innovative manufacturing devices, experienced and qualified engineers and workers, recognized good quality handle systems and also a friendly experienced income team pre/after-sales support for Top Suppliers Aluminum Conduit Corrosion Resistance - Resistor for Oil Drilling for braking resistor – Wepower , The product will supply to all over the world, such as: Istanbul, Namibia, Chile, Our products are widely recognized and trusted by users and can meet continuously changing of economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and mutual success!

The supplier cooperation attitude is very good, encountered various problems, always willing to cooperate with us, to us as the real God.